Introduction

With the increasing forest logging of humans, the natural resources of trees have become limited and largely less than before. People nowadays increase their awareness toward environmental protection and start to do something to decrease their harm to the earth. Due to the decreasing natural resources, it will be more difficult to obtain forest resources in the future.

As a result, some companies in the furniture industry have started to use plastic lumber to produce their products. Although plastic lumber is a type of relatively new material in the furniture industry, it has been widely used by many furniture manufacturers for the last 10 years. In the following paragraphs, I will provide you with deeper insights into why outdoor furniture suppliers nowadays are interested in using plastic lumber to enhance their business and product excellence.

Use of Plastic Lumber in Outdoor Funiture

What is Plastic Lumber?

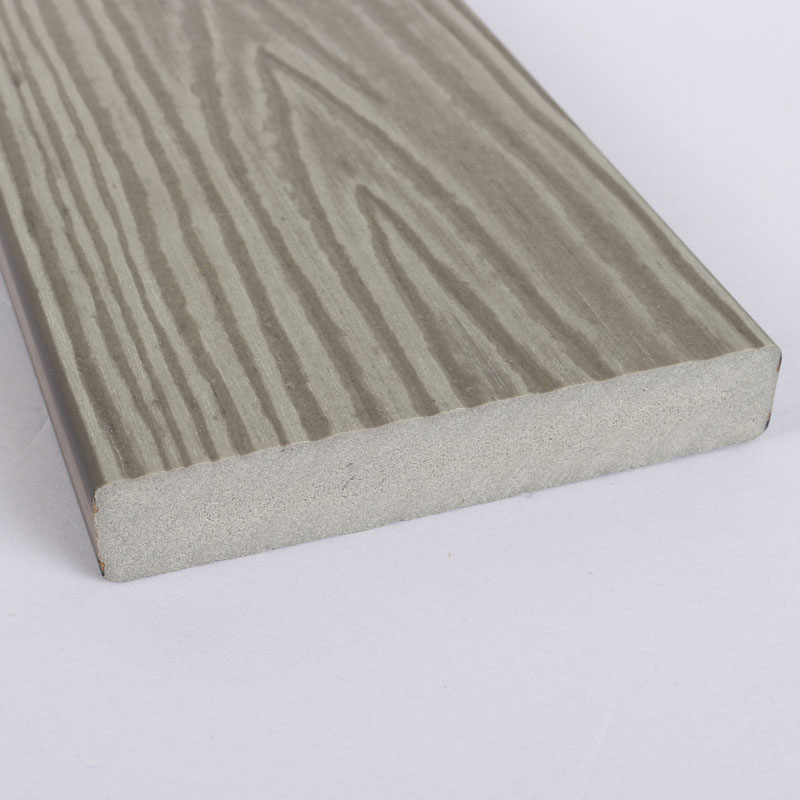

Plastic lumber, also known as recycled plastic wood, is a kind of popular furniture material in the furniture industry, especially in the outdoor furniture industry since it is an excellent substitution for traditional wood. Plastic wood is normally made from a blend of recycled plastic materials, such as high-density polyethylene (HDPE), polystyrene (PS), or polyvinyl chloride (PVC) with additives for enhancing strength and stability. Plastic lumber imitates the grains and texture of real wood, which makes its appearance look similar to traditional real wood. In addition to its wonderful wood-like appearance, plastic lumber also has some benefits that make it suitable for outdoor use.

For example, plastic lumber has strong resistance to rot, moisture, sunshine, and insects, which means it can undergo various harsh outdoor elements and can provide you with a carefree outdoor leisure moment. Therefore, plastic wood is commonly used by many furniture manufacturers. You can often see lots of things that are made of plastic lumber around you, for example, outdoor dining sets and bar sets in some outdoor commercial or residential areas, some long benches beside the paths in the parks, fencing, decking, landscaping and other indoor and outdoor furniture… All this furniture is normally made of plastic wood as it needs minimum maintenance by humans and can last longer in both indoor and outdoor environments, offering a sustainable option for people.

Plastic Lumber VS. Wood-Plastic Composites

Whenever people talk about this topic, it is easy for them to mess up these two materials. Most people including some furniture suppliers, might also be confused about these two terms and always interchange these words while describing some furniture. However, they are two kinds of materials that not only vary in the ingredient components but also vary in the scenarios they are used. Firstly, wood–plastic composites (WPCs) are composite materials made of wood fibre/wood flour and thermoplastic(s) such as polythene (PE), polypropylene (PP), polyvinyl chloride (PVC), or polylactic acid (PLA). Simply speaking, compared to plastic lumber that we mentioned above, wood-plastic composites (WPCs) have real wood flour inside, however, plastic lumber does not include any real wood materials, and it is completely made of plastics.

Secondly, due to the various densities of these two materials, their applications in the furniture industry are different. For wood-plastic composites which have higher density, are more suitable for use in indoor and garden decking, offering a more sturdy and carefree environment for you. By contrast, exquisite plastic wood is more suitable to be used in furniture making or home decoration due to its wonderful durability, processability, and minimal maintenance. Therefore, plastic wood is popular for furniture manufacturers, engineering contractors, and designers since it can be manufactured in various shapes and forms to satisfy customers’ needs.

Why Choose Plastic Wood Instead of Real Wood?

Although real wood has lots of benefits, there are still some concerns regarding its practicability in the outdoor furniture industry. Compared to plastic lumber, although the appearance of real wood is more natural and exquisite, and expresses the original and elegant beauty of wood, it is more expensive and not environmentally friendly. What is more, the weight of real wood is relatively heavy, which is not convenient for transporting and moving when it is used to make furniture. Besides, as for the materials of outdoor furniture, plastic wood has much better corrosion resistance and waterproofness, making it an ideal choice for outdoor use.

In terms of the manufacturing process, plastic lumber can be manufactured through injection moulding, extrusion, etc., while real wood requires manual processes such as cutting, grinding, and inlay. Although wooden material with handmade processes has a more complicated surface texture, machined plastic wood has a smoother surface that can be used in various kinds of furniture making.

Why Choose Plastic Wood Instead of Wood-plastic Composites?

When discussing this topic, some people might be wondering the same question towards wood-plastic composites as it is also a kind of plastic wood material that is normally used in the outdoor furniture industry. However, the practicality and durability of this material are not as strong as plastic wood due to its components. Although both wood-plastic composites and plastic lumber own the natural appearance of real wood and can be manufactured into various shapes, colours and patterns, plastic lumber still stands out as a premier outdoor furniture material.

First of all, compared to wood-plastic composite, plastic lumber is 100% made of plastics and does not include any wood flour; therefore, it has a greater resistance to corrosion and insects. What is more, when comparing the anti-water-absorbing capacity, plastic wood also performs better than WPC since real wood flour will affect the functionality of WPC to some extent. As a type of material that is entirely made of plastics, plastic lumber does not absorb any water, making it a more durable material than wood-plastic composite. If you are interested in producing some long-lasting and aesthetic outdoor furniture with low maintenance efforts for gardens or patios, plastic lumber will be your ideal material choice!

Secondly, although both materials are environmentally friendly, plastic lumber brings more positive effects to the forest since it is completely made of plastics. Furthermore, since outdoor furniture needs to be exposed to strong sunshine for a long time, its weatherability also matters a lot. Plastic lumber is also superior in terms of this ability. Therefore, as an outdoor furniture supplier or a project engineer, you would probably be more willing to choose plastic wood to produce the furniture.

Where to Purchase High-Quality Plastic Lumber?

After reading the above paragraphs, have you become more interested in plastic lumber? It is time for you to get your reliable furniture material. When you are selecting a suitable plastic lumber supplier, please keep in mind to check the capacities of the material. For example, as an outdoor furniture material, you should pay attention to its resistance to various outdoor situations such as strong sunshine exposure, insects, dust, heavy wind, rain, etc. What is more, as a type of material that is allowed for diversified manufacturing, you can choose a supplier that has a strong backup factory and advanced manufacturing skills to customize your products. As a result, you can get your ideal materials to satisfy your different customers’ needs. Leisure Touch Rattan, stands out as a professional and experienced rattan and plastic wood supplier, always dedicated to designing and offering sustainable, safe, and innovative plastic wood to its customers. The customisation option of plastic wood’s colours and patterns can fulfil your and your customer’s preferences and needs, helping you create a pretty, relaxing, and comfortable outdoor environment.

Conclusion

In general, outdoor furniture suppliers opt for plastic lumber to elevate their products due to its superior qualities compared to wood-plastic composite (WPC) or real wood. Plastic lumber offers unparalleled durability, resisting rot, decay, and insect damage, ensuring furniture withstands outdoor conditions for years. Unlike WPC, which may degrade over time, plastic lumber requires minimal maintenance and boasts a prolonged lifespan, offering enhanced value to both suppliers and consumers. Moreover, its versatility allows for innovative designs and customization, meeting diverse consumer preferences.

Additionally, the use of recycled plastic in manufacturing reduces environmental impact, promoting sustainability and circular economy principles. By choosing plastic lumber, outdoor furniture suppliers not only deliver long-lasting, low-maintenance products but also contribute positively to environmental conservation, making plastic lumber the preferred choice for sustainable outdoor furnishings. If you are interested in high-quality and stylish plastic wood, please check LTR’s website for more information!