Introduction

Wicker furniture has been around for thousands of years. The earliest known wicker furniture dates back to ancient Egypt and was made from reeds. Over the years, the use of wicker has evolved, and today it is made from a variety of materials, including natural and synthetic fibres.

One of the main benefits of wicker furniture is its durability. Wicker furniture is designed to last many years and withstand daily use’s wear and tear. Additionally, wicker furniture is very comfortable, making it a popular indoor and outdoor seating choice.

Materials

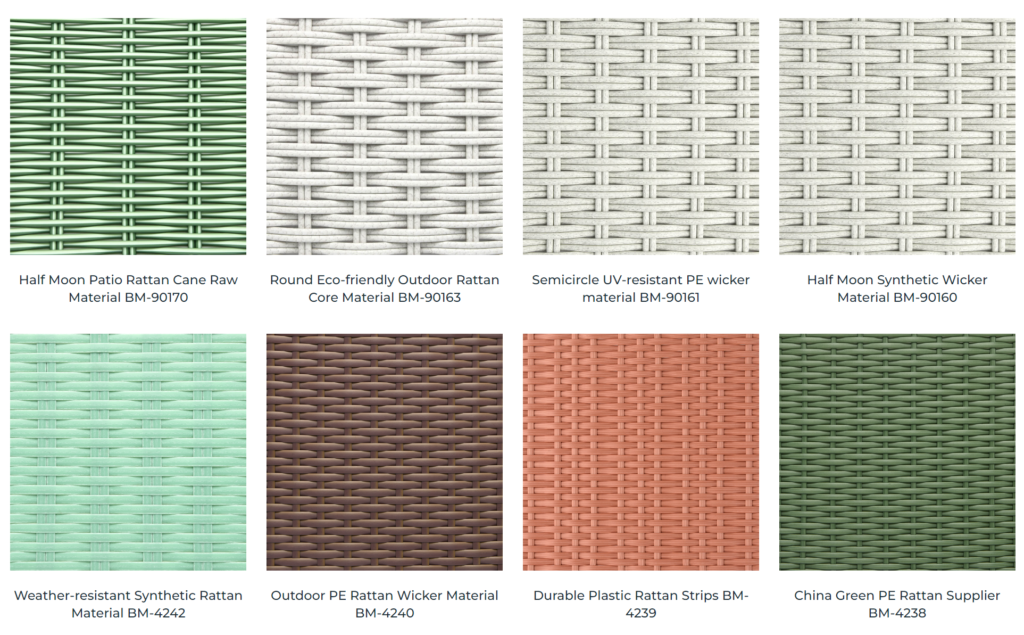

The materials used to make wicker furniture can vary depending on the manufacturer. However, most wicker furniture is made from natural or synthetic fibres. Natural fibres include materials like bamboo, rattan, and willow, while synthetic fibres can include materials like polyethene and resin.

The main difference between natural and synthetic wicker materials is their durability. Natural materials tend to be more delicate and require more maintenance, while synthetic materials are more durable and require less maintenance.

Before natural rattan can be woven into furniture, it must be prepared.

- First, the rattan is harvested from the forest and stripped of its outer bark.

- The inner core is then cut into sections and steamed to make it more pliable.

- Once the rattan has been steamed, it can be bent and woven into the desired shape for the furniture.

This process can take several days, depending on the complexity of the design.

Synthetic rattan does not require the same preparation as natural rattan. The fibres are usually made from polyethene and resin, extruded into long, thin strips. These strips are then dyed to the desired colour and used for weaving the furniture.

Weaving Process

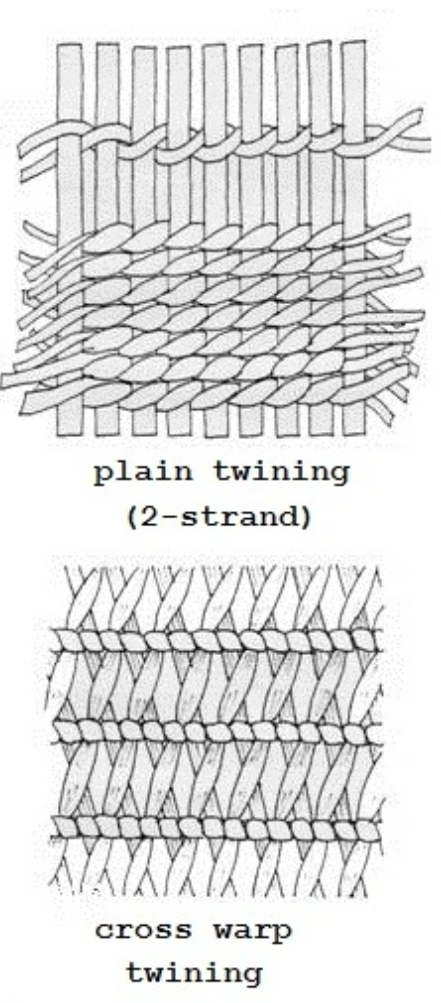

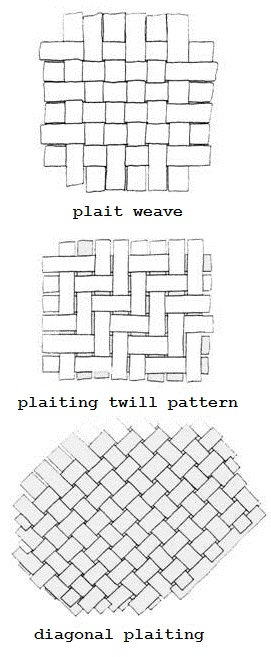

The weaving process is a critical part of making wicker furniture. The process involves weaving the fibres together to create the furniture’s unique pattern and design. Several different weaving techniques are used in wicker furniture, including over-under weaving, twining, and plaiting.

Over-under weaving is a common technique used in wicker furniture making where one fibre is woven over another and then under the next fibre, repeating the pattern until the desired design is achieved. This technique creates a tight and sturdy weave that contributes to the furniture’s overall strength and durability.

Twining is another common weaving technique used in wicker furniture making. This technique involves wrapping two strands of fibres around each other to create a stable and durable weave. Twining is often used to create intricate patterns and designs in wicker furniture.

Plaiting is another weaving technique used in wicker furniture making. It involves weaving three or more fibres together in an overlapping pattern to create a flat, braided design. Plaiting is often used to create borders or accents on wicker furniture.

The weaving process can be time-consuming, but it is essential to the furniture’s overall durability and strength.

Frame Construction

The frame construction process involves creating the structure of the furniture. The frames can be made from a variety of materials, including aluminium, steel, and wood. The frames must be strong enough to support the woven fibres and provide stability to the furniture.

Several types of frames are used in wicker furniture, including solid frames, split frames, and laminated frames.

Solid frames are one type of frame used in wicker furniture construction. They are made from a single piece of material, such as a solid piece of wood or a single piece of metal, and provide excellent stability and durability to the furniture.

Split frames are another type of frame used in wicker furniture construction. They are made from two or more pieces combined to create the frame. Split frames provide an excellent balance of stability and flexibility, making them popular for wicker furniture construction.

Laminated frames are another type of frame used in wicker furniture construction. They are made by layering thin strips of material, such as wood or metal, and bonding them with adhesive. This process creates a strong and durable frame that can be shaped into a variety of designs. Laminated frames are popular for high-end wicker furniture because of their strength and versatility.

Finishing

The finishing process involves applying the final touches to the furniture. This can include applying a protective coating to the frame, adding decorative accents, and applying a sealant to the fibres to protect them from moisture and sun damage.

Several types of finishes are used in wicker furniture, including paint, stain, and varnish.

- Paint is a common finishing option for wicker furniture, and it can be applied in various colours.

- Stain is another popular finishing option used to enhance the natural colour of the fibres.

- Varnish can protect the fibres from moisture and sun damage while providing a glossy finish to the furniture.

Cost

The price difference between a real natural rattan chair and a synthetic one can be significant. This is primarily due to the complicated process of growing, harvesting and processing natural rattan, which requires skilled labour and time. The process starts with harvesting the rattan from the forest and stripping it of its outer bark. The inner core is then cut into sections, steamed to make it pliable, and woven into the desired shape for the furniture. This process can take several days, depending on the complexity of the design.

In contrast, synthetic rattan is far more reasonable, especially in scale production. The fibres used to make this type of rattan are usually made from materials like polyethene and resin, which are extruded into long, thin strips. These strips are then dyed to the desired colour and used for weaving the furniture. The process is much simpler and faster, which makes it more cost-effective.

So, while a natural rattan chair can cost as much as $1000 due to the complexity of the process involved in making it, a synthetic one is much more affordable. This is because it can be mass-produced through a production line, using less labour and resources, resulting in a more reasonable price point.

Maintenance

Proper maintenance is essential to the longevity of wicker furniture. To help maintain your wicker furniture, keep it clean and dry, avoid exposing it to direct sunlight for extended periods, and store it in a dry place during the off-season.

If you need to repair or restore your wicker furniture, you can use several different techniques. For example, you can use a steam cleaner to remove dirt and grime or special spray paint to restore the colour of the fibres.

Recommended Synthetic Rattan Manufacturer

We recommend LTR as a reliable manufacturer of synthetic rattan in China. Founded in 1993, LTR has extensive experience in developing and producing PE rattan and PS plastic wood boards. We provide free samples and customization services to meet your specific needs.

Contact us for a quote and discover more about our product collections and exceptional service.

Conclusion

Wicker furniture is a popular choice because of its unique design, durability, and comfort. To maintain it, keep it clean and dry, avoid direct sunlight, and store it in a dry place off-season. Wicker furniture is also eco-friendly; maintenance includes regular cleaning and protecting it from the sun. Store it indoors during the off-season to prevent damage. With proper care, it can last for years and become a family heirloom.

Talk to our specialists today for more information about synthetic wicker furniture and its materials.