- Synthetic Rattan Products

- Customisation

- Application

- Service

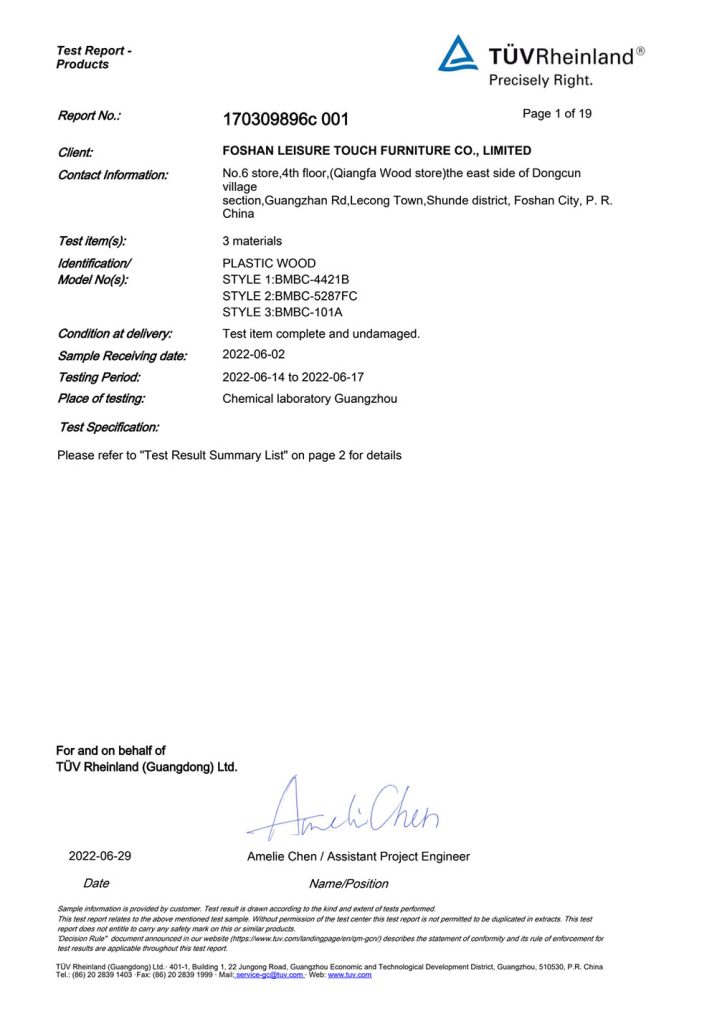

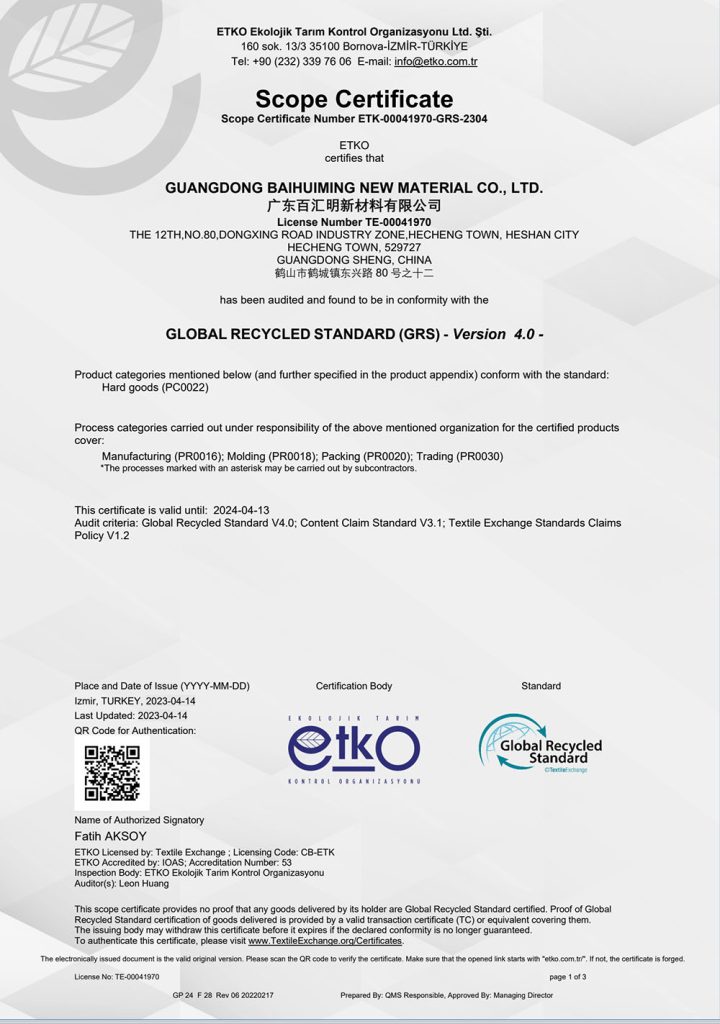

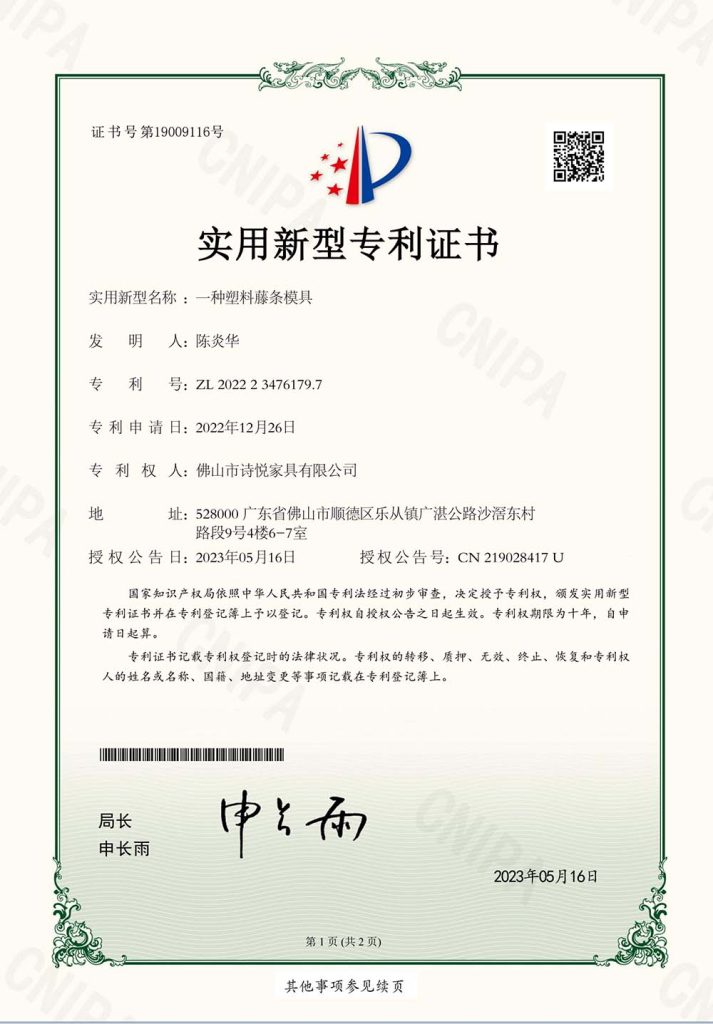

- Certification

PLASTIC WOOD BOARD EXPERT

Chinese Leading Manufacturer of

Outdoor Furniture Material

with 30 Years Experience

Convincing

Figures of LTR

548,98.18 m²

548,98.18

m²

Factory Size

1,120 Tons / Year

Plastic Rattan

2,800 Tons / Year

Plastic Wood Board

200+

Units

200+ Units

Extrusion Machines

Explore More Plastic Wood Board Products for

All Outdoor Needs

Trusted Outdoor Furniture Materials Supplier in China

100% Customisation

Create outdoor furniture materials with high-end customisation.

98% Good Quality Rate

Provide any outdoor furniture with superior durability and service life.

100%

Eco-friendly

GRS proved and produced with low carbon emissions.

100% Eco-friendly

GRS proved and produced with low carbon emissions.

90% Automated Production

With 7 days of free proofing, get your materials in a short time.

leisuretouch

Send Your Inquiry

*We respect your confidentiality and all information are protected.

*Please upload only jpg, png, pdf, dxf, dwg files. *Size limit is 10MB.

Explore Further Possibilities for Every Material

Explore Further Possibilities

for Every Material

Custom Outdoor Furniture Material that’s Distinctly Yours

Size

Colour

Shape

Finishing

Texture

Exquisitely Made For Outdoor Furniture

The patented plastic wood board from LTR allows manufacturers and carpenters to create outdoor furniture that can withstand the outdoor elements. In addition, LTR boards are a sustainable solution for making beautiful wooden furniture.

Patented Design

Non-cracking

Resists Termites

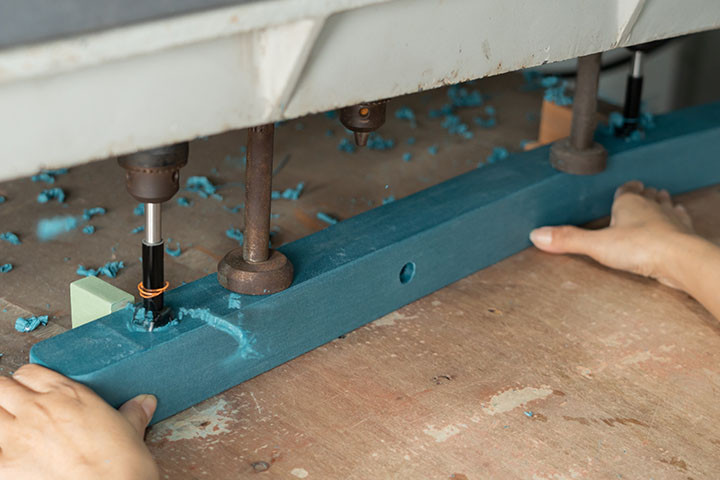

Available for stapling, planing, sawing and drilling

Tailor-made Services That Transform Your Brand

Exquisite Material from Competent Factory

The Fine Production of Plastic Wood

With a focus on quality, durability, productivity and eco-friendliness, our wood products are not only visually appealing and practical, but also a responsible choice for customers who care about the planet.

Thanks to our tip top sparking machines, sawing machines, water mills, CNC machines, drilling machines, extrusion machines and injection molding machines etc., we can produce high quality and unique plastic wood products to meet your particular requirements and preferences.

Shaping Quality Excellence of Wood Boards

We meticulously followed a number of processes in the manufacture of plastic wood board in order to create a completed product of the finest quality.

It usually involves combining all of the essential raw ingredients, including HDPE, PS, and antioxidant, and then mixing and blending them in a precise ratio for the production process according to our own formula.

After the mixing process is complete, the mixture is fed into an extruder. The extruder heats the mixture to a high temperature, and the melted mixture is then forced through a die to form the shape of board. The extruded board is then cooled using a water bath to solidify it.

The molded boards are pressed and shaped using a hydraulic press. This process ensures that the boards have a consistent shape as you required.

The boards are flattened under high pressure with our automatic machines. This cutting process involves using a variety of cutting tools, including CNC machines, drills, and saws, to cut the desired size of the boards.

The boards are treated to improve their appearance and durability. We offer a range of surface treatments, including embossing, polishing, and sanding. These treatments help to create a smooth and attractive surface, while also improving the board's resistance to scratches and stains.

The final step in the plastic wood board manufacturing process is packaging. The boards are carefully stacked and wrapped in carton with a protective PE foam cover to ensure that they arrive at their destination in perfect condition.

Applications in Furniture Making

Proof of Reliability

Equip Your Furniture Factory with Advanced Solution

Materials + Training

A Variety of Products

We provide you with all the materials needed for production, including aluminum tubes, plastic rattan and wood, and plastic accessories.

Professional Instruction

To prepare your team for the task ahead, we will send you seasoned instructors(at least 2) that will impart time-tested manufacturing techniques and efficient furniture processes.

Materials + Equipments + Training

Abundant Product Portfolio

From aluminum tubes to plastic rattan and wood pieces, we will supply you with all the materials you need to help you fulfill your outdoor furniture project.

Equipment Sourcing

We will then source the equipment you’ll need for the project, like cutting machines, bending, and drilling machines, among others.

Clear Coaching

Our instructors will continue to provide expert coaching and direction to ensure you’re well-equipped to create outdoor furniture.

Proof of Reliability

Angela Jensen

Procurement Manager

Very good customer care. They have genuinely good quality products with reasonable prices. Timely shipping will recommend you buy from them.

Ron

Procurement Manager

I am very satisfied with plastic wood.

The seller is very cooporative, quick responding, helpful & very Professional. Product quality is outstanding too.

Kasey

Procurement Manager

Great experience working with Leisure Touch. The seller is very responsive to all my queries. Great customer service.

YOUR ONE-STOP SUPPLIER FOR PLASTIC WOOD BOARD

Nature's Best for Outdoor Rest: Plastic Wood Board

Copyright @ 2023, Leisure Touch Rattan. All rights reserved.